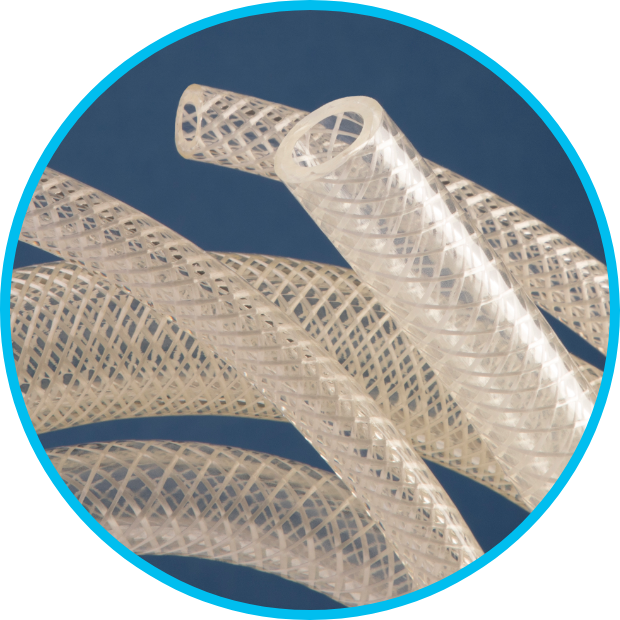

Urebrade® Braid Reinforced

Polyurethane Hose

Features

- Open mesh polyester braiding incorporated within the wall of flexible, ether-based polyurethane

- Offers much greater pressure capability than unreinforced polyurethane tubing

- Made from non-toxic raw ingredients conforming to FDA standards

- Resin is listed by the National Sanitation Foundation (NSF-61) for use with potable water

- Resistant to weathering†, tearing, impact, abrasion, radiation exposure, oils, greases, and fuels††

- Wide range of temperature resistance; -90°F to 175°F

- Free of DEHP, phthalates, BPA and conflict minerals

- RoHS compliant

- Naturally transparent for visual contact with the flow

Applications

Abrasive Powder Transfer • Agricultural Lines • Air Tools • Cement Slurries • Granular Transfer • Hydraulic Lines • Lubricated Air Feeds • Lubrication Lines • Nuclear Power Facilities • Oil & Fuel Lines†† • Petroleum Products Transfer†† • Robotics • Transfer Lines for Clean Liquids • Transfer Lines for Internal Contamination Fluids • Well Pipe & Cable Jacket

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore A ±5

Tensile Strength, psi

Elongation at Break, %

Brittle Temperature, °F

Max. Operating Temperature, °F

85

5500

580

-90

175

Notes

†Hydrolytic Stability — UREBRADE is supplied in an ether formulation, making it resistant to attack from moisture and fungi. The resin used in UREBRADE is listed by the National Sanitation Foundation (NSF 61).

Where applications involve repeated flexing, heavy vibration, or abrasion, UREBRADE offers superior service life over other materials.

Ester-based UREBRADE is available through minimum order — call for details.

††Due to additives in today’s gasoline and petroleum products, field testing should be performed.

For easy identification, transparent UREBRADE is imprinted with the trademarked name.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

| Part Number | Note | ID (in.) | OD (in.) | Wall (in.) | Available Lengths (ft.) | Working PSI (at 70°F) | Bend Radius (in.) | Weight (lbs./100 ft.) |

|---|---|---|---|---|---|---|---|---|

| 2200072 | [B] | .250 | .470 | .110 | 50, 100 | 250 | .750 | 6.04 |

| 2200149 | [B] | .375 | .630 | .127 | 50, 100 | 190 | .750 | 9.78 |

| 2200226 | [B] | .500 | .750 | .125 | 25, 50, 100 | 150 | 1.500 | 11.92 |

| 2200303 | .625 | .905 | .140 | 100 | 130 | 2.000 | 16.34 | |

| 2200380 | .750 | 1.025 | .137 | 50, 100 | 100 | 3.000 | 18.62 | |

| 2200457 | [B] | 1.000 | 1.300 | .150 | 25, 50, 100 | 80 | 3.500 | 26.32 |

| 2200534 | 1.250 | 1.710 | .230 | 50, 100 | 75 | 4.000 | 51.94 | |

| 2200611 | [B] | 1.500 | 1.930 | .215 | 50, 100 | 50 | 5.500 | 56.26 |

| 2200688 | 2.000 | 2.500 | .250 | 100 | 40 | 7.500 | 85.82 |

[B] Limited stock item; lead times and minimums may apply — call for details.

Add length suffix to part number when ordering. Example: 100 ft. of 1/4″ I.D. x .470″ O.D. standard hose is part number 220 0072-100.

Working pressures are calculated from burst testing using a 4:1 safety factor. Application testing is recommended.

Cut coils available; charges apply — call for details.

Due to the coil diameter, some larger sizes must ship via truck.

ID is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

Size

Color

Hot Bond

Heat Form

Hardness

In-Line Cutting

Custom Layline

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.