Coiltef™ Coiled FEP

Fluoropolymer Tubing

Features

- Made of chemically inert clear FEP

- Manufactured from FDA compliant materials

- Heat set into a retractable coil; excellent recoil memory

- Offers all the chemical and electrical insulation properties of standard FEP fluoropolymer tubing

- Allows flexibility to otherwise semi-rigid fluoropolymer tubing

- All Coiltef is made to order — call for details

Applications

Chemical Hose • Deionized Water Transfer • Dispensing Systems • Industrial Laboratory Uses • Paint Spray Systems • Pure Air Systems • Pure Water & Fluid Systems • Robotics

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore D

Tensile Strength, psi

Elongation at Break, %

Brittle Temperature^^, °F

Min. Operating Temp. for Tubing^^, °F

Max. Operating Temp. for Tubing^^, °F

55-60

2800-5000

250-330

-450

-100

200

^^ Temperatures are for standard extruded (non-coiled) tubing. See “Notes” for additional information.

Notes

Almost totally inert, COILTEF can be used with all industrial solvents, chemicals, and corrosive materials even at elevated temperatures. It does, however, react with fluorine, molten sodium hydroxide, and molten alkali metals.

Fluoropolymer’s non-stick property allows transport of viscous, sticky material without line clogging. It also offers outstanding aging resistance.

COILTEF is manufactured through a fabrication process which heat sets the coils. The coils should remain stable up to 200°F. At higher temperatures the coils will begin to relax and lose their set. If the application involves elevated temperatures, in-house testing is recommended.

COILTEF may be steam or chemically sterilized in-line with any industrial cleaner, solvent, or sterilizing method. Care should be taken with steam sterilization of COILTEF to prevent coil relaxation. Testing is recommended.

COILTEF can be manufactured from .085” to 1/2” tubing ID. The coil diameter can be produced from 3/4” OD to 4” OD. PFA formula is available by special order only.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

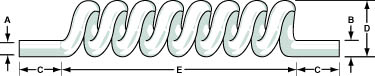

| Part Number | Note | (A) ID (in.) | (B) OD (in.) | Wall (in.) | (D)Nominal Coil OD | (E)Nominal Max Expanded Length Excluding Tails (in.) | (C)Tail Lengths (in.) |

|---|---|---|---|---|---|---|---|

| 3600072 | [AY] | .063 (1/16) | .188 (3/16) | .063 (1/16) | 1.125 (1-1/8) | 12, 24, 48 | 6 |

| 3600149 | [AY] | .125 (1/8) | .250 (1/4) | .063 (1/16) | 1.500 (1-1/2) | 12, 24, 48, 72 | 6 |

| 3600226 | [AY] | .188 (3/16) | .313 (5/16) | .063 (1/16) | 2.250 (2-1/4) | 12 | 6 |

| 3600303 | [AY] | .250 (1/4) | .375 (3/8) | .063 (1/16) | 2.375 (2-3/8) | 12, 24, 48, 72 | 6 |

| 3600457 | [AY] | .375 (3/8) | .500 (1/2) | .063 (1/16) | 4.000 | 24, 48 | 6 |

[AY] Non-stock item; lead times and minimums may apply – call for details.

Add length suffix to part number when ordering.

Example: 12″ of 1/16″ I.D. x 3/16″ O.D. tubing is part number 360 0072-12.

The retracted length is approximately 1/4 of the maximum expanded length excluding tails.

Wall thickness for all standard sizes is 1/16. Tail length (item C) is six inches for all listed sizes.

OD is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.