Prolite®

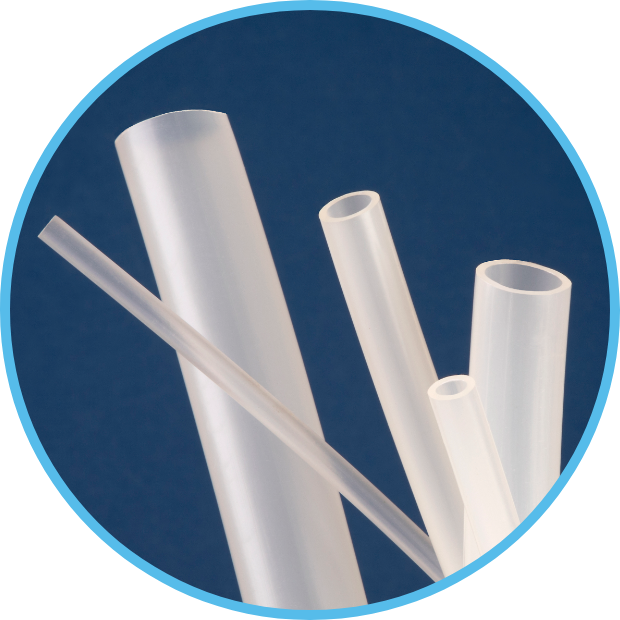

Polypropylene Tubing

Features

- Polypropylene homopolymer made from ingredients that meet FDA requirements for food contact surfaces

- Animal-free ingredients

- No phthalates used in the manufacture of its ingredients

- Extremely lightweight, thermoformable and weldable

- Extremely low moisture absorption

- Excellent chemical resistance

- Naturally translucent white in appearance

- May be used as a lower-cost alternative to fluoropolymer tubing

Applications

Compressed Air • Dispensing Equipment • Environmental Monitoring • Food & Beverage Lines • Instrumentation • Personal Care Products • Potable Water Systems • Refrigeration • Semiconductor Manufacturing • Vacuum Systems

Recommended

Fittings & Clamps

Physical Properties**

Tensile Strength, psi

Elongation at Break, %

Max. Operating Temp., °F

4900

13

125

Notes

PROLITE is made from a compound that exhibits good heat aging resistance. It meets the FDA requirements for the safe use of olefin polymers used to make articles intended for food contact per FDA 21 CFR 177.1520.

PROLITE is frequently used in food processing and other industries for clean applications. It is a naturally white, semi-rigid product offering limited ability to bend. Since it is weldable, PROLITE may be joined directly, although it is typically joined by means of a push-to-connect fitting such as Newloc®.

Polypropylene is the lightest of all thermoplastic materials. It offers high strength- to-weight ratio, low surface friction, and excellent resistance to corrosion.

Other sizes are available through minimum order — call for details. Samples of stock material are available upon request.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

| Part Number | Note | ID (in.) | OD (in.) | Wall (in.) | Available Lengths (ft.) | Working PSI (at 70°F) |

|---|---|---|---|---|---|---|

| 4480070 | .125 (1/8) | .250 (1/4) | .062 (1/16) | 100 | 250 | |

| 4480147 | .170 | .250 (1/4) | .040 | 100 | 149 | |

| 4480224 | .187 (3/16) | .313 (5/16) | .062 (1/16) | 100 | 196 | |

| 4480301 | .250 (1/4) | .375 (3/8) | .062 (1/16) | 100 | 157 | |

| 4480378 | .375 (3/8) | .500 (1/2) | .062 (1/16) | 100 | 112 | |

| 4480455 | .500 (1/2) | .625 (5/8) | .062 (1/16) | 100 | 87 | |

| 4480609 | .625 (5/8) | .750 (3/4) | .062 (1/16) | 100 | 71 | |

| 4480651 | .750 (3/4) | 1.000 | .125 (1/8) | 50 | 109 | |

| 4480840 | [B] | 1.000 | 1.250 (1-1/4) | .125 (1/8) | 50 | 87 |

[B] Limited stock availability; lead times and minimums apply- call for details.

Add length suffix to part number when ordering. Example: 100 ft. of 3/16″ I.D. x 5/16″ O.D. tubing is part number 448 0224-100.

Sizes larger than 1-1/4″ O.D. are available — call for details.

Due to the coil diameter, some larger sizes must ship via truck.

OD is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.