Contef™ Convoluted PTFE

Fluoropolymer Tubing

Features

- Translucent PTFE tubing offers excellent chemical and electrical properties

- Available from stock with or without a stainless steel wire encircling the O.D.

- Wire coil provides increased pressure capability and aids in electrical grounding

- Easily flexed – spiral construction allows far greater flexibility than straight wall tubing

- Spiral construction also allows for easier cleaning

- Made from FDA compliant materials

Applications

Chemical Processing • Deionized Water Transfer • Industrial Laboratory Uses • Paint Spray Systems • Processing & Packaging • Robotics • Ultra-Pure Fluid Systems

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore D

Tensile Strength at Break, psi

Elongation at Break, %

Embrittlement Temperature, °F

Min. Operating Temp. for Tubing^^, °F

Max. Operating Temp. for Tubing^^, °F

50-65

3500

200-400

-450

-100

500

^^ Temperatures are for standard extruded (non-convoluted) tubing.

Notes

CONTEF’s helical construction aids in self-cleaning when flushed with standard cleaning fluids.

The cuffs (straight ends) are made to accept standard barbed fittings. Hose assemblies made to your specifications are available.

PTFE’s color will vary naturally from lot to lot, but the quality and physical properties do not change.

FEP CONTEF for longer continuous lengths is available through custom order.

CONTEF Without Wire: Vacuum Service: 27 in.Hg at 72°F. The convolutions are molded into the tubing and will not cold flow into a straight wall under normal conditions.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

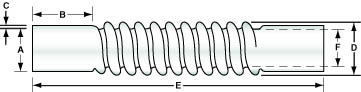

| Part Number | Construction | (A) ID (in.) | (B) Nom. Cuff Lengths (in.) | (C) Wall (in.) | (D) Nom. Convolution OD (in.) | (E) Max. Avail. Lengths - including cuffs (ft.) | (F) Nom. Convolution ID (in.) | Working PSI (at 72°F) | Burst PSI (at 72°F) | Bend Radius (in.) |

|---|---|---|---|---|---|---|---|---|---|---|

| 3500070 | Unreinforced | .250 (1/4) | .750 (3/4) | 0.015 | 0.32 | 125 | 0.181 | 45 | 180 | .500 (1/2) |

| 3500147 | Unreinforced | .313 (5/16) | 1.000 | 0.02 | 0.414 | 125 | 0.273 | 48 | 192 | .750 (3/4) |

| 3500224 | Unreinforced | .375 (3/8) | 1.000 | 0.02 | 0.45 | 125 | 0.303 | 40 | 160 | 1.750 (1-3/4) |

| 3500301 | Unreinforced | .500 (1/2) | 1.000 | 0.02 | 0.59 | 100 | 0.425 | 30 | 120 | 1.250 (1-1/4) |

| 3500378 | Unreinforced | .625 (5/8) | 1.250 (1-1/4) | 0.023 | 0.66 | 75 | 0.485 | 30 | 120 | 1.500 (1-1/2) |

| 3500455 | Unreinforced | .750 (3/4) | 1.500 (1-1/2) | 0.025 | 0.78 | 75 | 0.608 | 25 | 100 | 1.750 (1-3/4) |

| 3500532 | Unreinforced | 1.000 | 2.000 | 0.03 | 1.1 | 50 | 0.849 | 22 | 90 | 2.230 |

| 3500609 | Unreinforced | 1.250 (1-1/4) | 2.500 (2-1/2) | 0.035 | 1.56 | 40 | 1.15 | 21 | 85 | 2.750 (2-3/4) |

| 3500686 | Unreinforced | 1.500 (1-1/2) | 2.500 (2-1/2) | 0.04 | 1.91 | 40 | 1.41 | 20 | 80 | 3.000 |

| 3500763 | Unreinforced | 2.000 | 2.500 (2-1/2) | 0.043 | 2.45 | 40 | 1.955 | 16 | 65 | 4.250 (4-1/4) |

| 3520076 | Wire reinforced | .250 (1/4) | .750 (3/4) | 0.015 | 0.32 | 12 | 0.181 | 58 | 234 | .500 (1/2) |

| 3520153 | Wire reinforced | .313 (5/16) | 1.000 | 0.02 | 0.414 | 12 | 0.273 | 62 | 250 | .750 (3/4) |

| 3520230 | Wire reinforced | .375 (3/8) | 1.000 | 0.02 | 0.45 | 12 | 0.303 | 52 | 208 | 1.750 (1-3/4) |

| 3520307 | Wire reinforced | .500 (1/2) | 1.000 | 0.02 | 0.59 | 20 | 0.425 | 39 | 156 | 1.250 (1-1/4) |

| 3520461 | Wire reinforced | .750 (3/4) | 1.500 (1-1/2) | 0.023 | 0.78 | 20 | 0.608 | 32 | 130 | 1.750 (1-3/4) |

| 3520538 | Wire reinforced | 1.000 | 2.000 | 0.03 | 1.1 | 20 | 0.849 | 29 | 117 | 2.250 (2-1/4) |

“E” dimension to be specified at time of order. All lengths will be supplied with ‘B’ dimension cuffs.

All pressures are calculated and not based on actual testing.

ID is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.