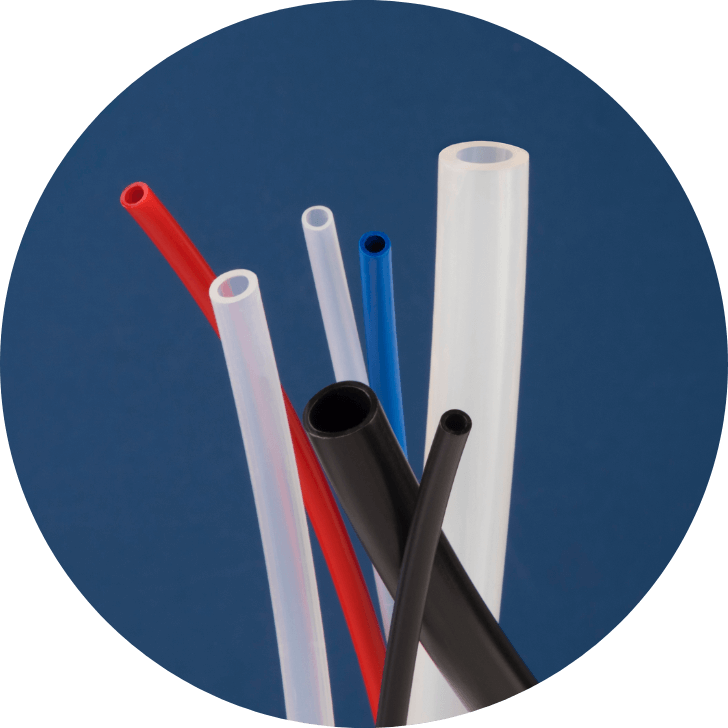

Polyethylene Tubing

Polyethylene (PE) has long been recognized as an engineering plastic that exhibits a high degree of inertness, making it attractive for use in markets such as food and beverage, laboratories, and chemical processing where leaching or permeability would present risks. Polyethylene is also one of the lower-cost plastic materials and satisfies many requirements that call for inexpensive, lightweight tubing. In fact, NewAge’s polyethylene tubing is so lightweight, it floats. PE tubing handles a wide variety of applications ranging from potable water feed or drain lines to pneumatic or signal lines used in instrumentation.

ZELITE™, NewAge’s brand of LLDPE tubing, is offered in a linear low density polyethylene formulation for repeated flexing with little or no signs of wear and for improved stress crack resistance over low density material. The resin is non-toxic, 100% virgin grade conforming to FDA requirements. ZELITE is a standard in the food and beverage processing and pneumatic industries, and its semi-rigid nature allows it to be used with push-to-connect fittings without clamps.

Polyethylene-lined EVA tubing (PE-LINED EVA) is a co-extruded product. The inner core of polyethylene is extruded first, then farther down the production line, EVA is extruded around the inner core. PE-LINED EVA is typically applied where different performance requirements for the inside and the outside of the tube are needed (purity inside, flexibility outside).

Polyethylene-Lined EVA Tubing

Co-Extruded Tubing

Learn More

Zelite™

Linear Low Density Polyethylene Tubing

Learn More

Suggested Applications

Air Lines • Appliances • Chemical Transfer • Computer Equipment • Conduit • Fluid Feeds • Food & Beverage Processing • Hospitals & Laboratories • Instrumentation • Pools & Spas Supply Lines • Potable Water Systems • Spacers • Water or Chemical Drains • Wire Jacketing • Many More