Zelite™ Linear Low Density

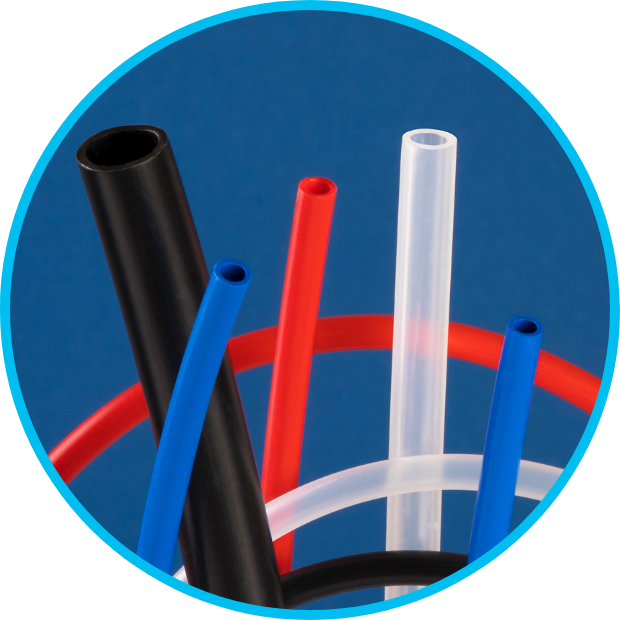

Polyethylene Tubing

Features

- Made from non-toxic ingredients conforming to FDA standards

- Does not impart a taste or odor to critical streams

- Flexible, lightweight, durable

- Translucent natural or opaque colors

- Made from 100% virgin grade raw materials

- Good dielectric properties

- Offers enhanced resistance to stress cracking

- Chemically inert; forms a good barrier to gases, vapors, and moisture

Applications

Air Lines • Chemical Lines • Fluid Feeds • Food & Beverage Processing • Hospitals & Laboratories • Instrumentation • OEM Large Machines • Spacers • Wire Jacketing

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore D ±5

Tensile Strength, psi

Elongation at Break, %

Brittle Temperature, °F

Vicat Softening Point, °F

Max. Operating Temp., °F

50

2250

600

-76

196

140

Notes

ZELITE conforms to the applicable regulations of the FDA for use in articles intended for contact with food. The increased tensile strength of ZELITE Linear Low Density, over that of a low density polyethylene, enhances its resistance to splitting during use.

FEP-lined polyethylene, offering superior purity at a very reasonable cost, is available through minimum order. Medium-high and ultra-high density polyethylene material is available through minimum order. Call for details on these custom products.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

| Part Number | ID (in.) | OD (in.) | Wall (in.) | Available Lengths (ft.) | Working PSI (at 70°F) | Burst PSI (at 70°F) | Colors | Weight (lbs./100 ft.) |

|---|---|---|---|---|---|---|---|---|

| 2510214 | .125 (1/8) | .250 (1/4) | .063 (1/16) | 500 | 180 | 720 | Black | 1.47 |

| 2510256 | .125 (1/8) | .250 (1/4) | .063 (1/16) | 100, 500 | 180 | 720 | Natural | 1.47 |

| 2510529 | .170 | .250 (1/4) | .040 | 500 | 135 | 540 | Black | 1.05 |

| 2510543 | .170 | .250 (1/4) | .040 | 500 | 135 | 540 | Blue | 1.05 |

| 2510571 | .170 | .250 (1/4) | .040 | 100, 500 | 135 | 540 | Natural | 1.05 |

| 2510606 | .170 | .250 (1/4) | .040 | 500 | 135 | 540 | Red | 1.05 |

| 2510886 | .188 (3/16) | .313 (5/16) | .063 (1/16) | 100, 500 | 140 | 560 | Natural | 2 |

| 2511159 | .250 (1/4) | .375 (3/8) | .063 (1/16) | 500 | 120 | 480 | Black | 2.5 |

| 2511201 | .250 (1/4) | .375 (3/8) | .063 (1/16) | 100, 500 | 120 | 480 | Natural | 2.5 |

| 2512104 | .375 (3/8) | .500 (1/2) | .063 (1/16) | 500 | 90 | 360 | Black | 3.5 |

| 2512146 | .375 (3/8) | .500 (1/2) | .063 (1/16) | 100, 500 | 90 | 360 | Natural | 3.5 |

| 2512279 | .500 (1/2) | .625 (5/8) | .063 (1/16) | 100 | 70 | 280 | Black | 4.4 |

| 2512293 | .500 (1/2) | .625 (5/8) | .063 (1/16) | 100 | 70 | 280 | Natural | 4.4 |

| 2512398 | .625 (5/8) | .750 (3/4) | .063 (1/16) | 100 | 60 | 240 | Natural | 5.4 |

| 2512713 | .750 (3/4) | 1.000 | .125 (1/8) | 100 | 90 | 360 | Natural | 13.7 |

| 2512818 | .875 (7/8) | 1.000 | .063 (1/16) | 100 | 45 | 180 | Natural | 7.4 |

| 2512923 | 1.000 | 1.250 | .125 (1/8) | 100 | 72 | 288 | Natural | 17.6 |

| 2513028 | 1.250 | 1.500 | .125 (1/8) | 50 | 59 | 236 | Natural | 21.5 |

| 2513133 | 1.500 | 1.750 | .125 (1/8) | 50 | 50 | 200 | Natural | 25.5 |

Add length suffix to part number when ordering. Example: 500 ft. of .170″ I.D. x 1/4″ O.D. red color tubing is part number 251 0606-500.

OD is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

Size

Color

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.