Kinks in tubing can cause a lot more trouble than one would expect. They disrupt fluid flow, jeopardize product integrity, and even pose safety risks. So, how does one tackle the multifaceted issue of keeping fluid systems running smoothly?

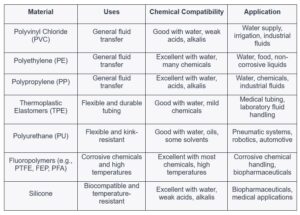

The first step is to choose the right tubing material for your application. Some materials are more kink-resistant than others. For example, polyurethane is a good choice for applications where the tubing will be flexing frequently, while silicone is a better choice for medical applications where biocompatibility and temperature resistance are important. Below, we’ve tabled several materials, their uses, chemical compatibility, and possible applications.

Once you’ve chosen a material, it’s important to install and manage the tubing properly. Below are some techniques:

• Avoid sharp bends; opt for gradual, smooth bends with the right bending radius, following the tubing manufacturer’s recommendations. Consider using a bending spring or tube bender for precision.

• When changing direction, use elbow fittings instead of forcing sharp turns. Elbows help preserve tubing integrity and reduce the risk of kinking.

• Do not exceed the tubing’s recommended limits, as overstretching can create stress points and lead to kinking.

• Provide enough slack in the tubing to accommodate movement and system changes without tension. However, avoid excessive slack that may cause sagging.

• Use clamps, brackets, or other fixtures to securely support the tubing’s route, preventing accidental compression or damage.

• Inspect the tubing regularly for signs of kinking, wear, or damage. Replace any compromised tubing to maintain system integrity.

Following these tips can help you avoid tubing kinks and keep your system running smoothly.

To gain a more in-depth understanding of this topic, including insights into external factors that can cause your tubing to kink, studies, and more, be sure to grab your free copy of our most recent white paper!

White Papers & Case Studies

If you wish to talk about solutions with someone from our team phone us at 800-506-3924 or +1-215-526-2300,

e-mail info@newageindustries.com,

or use the Contact Us form below.