Tubing Tip #8: Reuse

Taking the time to learn whether tubing or hose can be reused can help reduce your costs. Although plastic tubing is often considered a disposable item, it doesn’t always have to be. So, finding out if the tubing in your application can be cleaned and used again in that application, or repurposed for another, can save you money.

Learn whether the tubing can handle one or more standard cleaning methods. Other important information to know is how many cycles (how many times) it may be cleaned using the same procedure. If there’s a recommended limit, can you then switch to another method? Testing for your specific application is recommended.

Research the best cleaning methods for the type of tubing material you have in mind. Can it be autoclaved? Low-pressure steam sterilized? Cleaned with a specific chemical? Can it handle the abrasion of a cleaning tool like a brush? Does the application call for a simple flush with water?

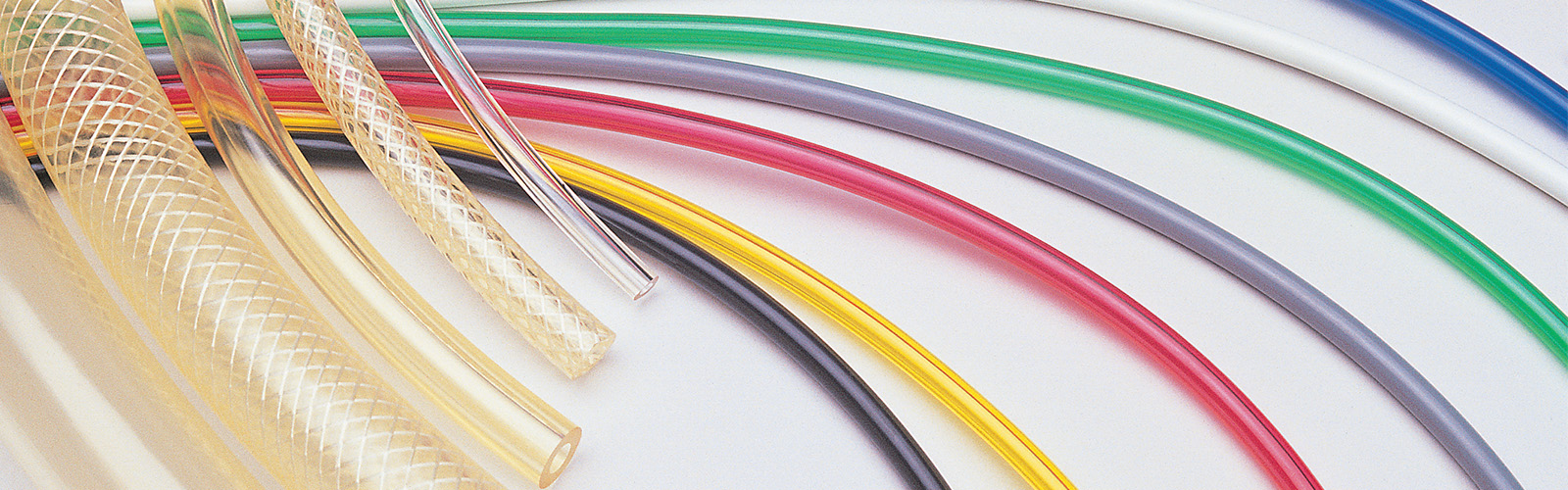

Some plastic tubing materials such as polyurethane and PVC are quite durable and chemical resistant. Other materials may handle high temperatures well but not certain cleaning fluids. Depending on the tubing material and cleaning method used, tubing may:

-Become brittle and prone to cracking

-Become tacky or gummy

-Break down chemically

-Loose its shape

-Absorb the cleaning agent

Consider, too, that depending on the labor, equipment, and resources involved with cleaning or sterilizing the tubing or hose, it may be more efficient to replace it. Lower cost materials (polyethylene, PVC, nylon) may not warrant cleaning like multi-layer hoses or special materials and styles (Viton, coiled fluoropolymer, braid reinforced silicone).

Be sure to research and select tubing or hose that meets your application’s requirements.

You can find part one and two of our Top 20 Tubing and Hose Buying Tips here.

If you wish to learn more from our helpful staff, connect with our team by completing the following form.