Corrtef™ Corrugated FEP

Fluoropolymer Tubing

Features

- Made from FEP fluoropolymer tubing

- Corrugations allow a nearly zero bend radius – easily flexed

- Can be extended or compressed without affecting the tube’s I.D.

- Made without plasticizers which can leach into critical streams

- Made from FDA compliant materials

- Has all the chemical and electrical properties of straight-walled FEP tubing

- May be overbraided with Kevlar® for higher pressures^

Applications

Chemical Processing • Corrosives • Deionized Water Transfer • Hot Glue • Industrial Laboratory Uses • Paint Spray Systems • Pure Fluid Systems • Solvent Transfer

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore D

Tensile Strength, psi

Elongation at Break, %

Brittle Temperature^^, °F

Min. Operating Temp. for Tubing^^, °F

Max. Operating Temp. for Tubing^^, °F

55-60

2800-5000

250-330

-450

-100

200

^^Temperatures are for standard extruded non-corrugated tubing.

Notes

Vacuum Service at 72°F: 29.9 in./Hg.

Bend Diameter at 72°F: 1/2 of tubing I.D.

Optimal flow is achieved and turbulence minimized by passing fluids through CORRTEF in the direction of the corrugation angles (as noted).

CORRTEF is heat sealable, and the cuffs (straight ends) are made to accept standard barbed fittings. The end may be flared or expanded to permit shrink-tight connections.

CORRTEF is manufactured in an industrial atmosphere and should be properly sterilized for clean-flow applications. For optimal cleaning of CORRTEF the tube should be stretched to its maximum length and held vertically (direction of flow: down). NOTE: Due to the annular corrugations, it may not be possible to remove all traces of particulate from CORRTEF, even under optimal cleaning conditions.

^Overbraiding with Kevlar® will permit a minimum increase of 6X the listed pressures. Kevlar overbraiding is available for sizes up to 7/8” I.D. – call for details.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

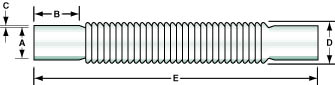

| Part Number | (A)MAX ID (in.) | (B)Nominal Cuff Lengths (in.) | (C) Wall (in.) | (D)Corrugation OD (in.) | (E)Maximum Available Lengths - including cuffs (ft.) | Working PSI(at 72°F) | Burst PSI (at 72°F) |

|---|---|---|---|---|---|---|---|

| 3400075 | .250 (1/4) | .750 (3/4) | 0.015 | .375 (3/8) | 12 | 62 | 248 |

| 3400152 | .375 (3/8) | 1.000 | 0.02 | .625 (5/8) | 12 | 50 | 200 |

| 3400229 | .500 (1/2) | 1.000 | 0.025 | .750 (3/4) | 12 | 42 | 168 |

| 3400306 | .625 (5/8) | 1.000 | 0.025 | .938 (15/16) | 12 | 37 | 148 |

| 3400383 | .750 (3/4) | 1.500 (1-1/2) | 0.03 | 1.063 (1-1/16) | 12 | 30 | 120 |

| 3400460 | .875 (7/8) | 1.500 (1-1/2) | 0.03 | 1.250 (1-1/4) | 12 | 25 | 100 |

| 3400537 | 1.000 | 2.000 | 0.035 | 1.438 (1-7/16) | 12 | 20 | 80 |

| 3400691 | 1.500 (1-1/2) | 2.000 | 0.035 | 1.813 (1-13/16) | 12 | 15 | 60 |

| 3400768 | 2.000 | 2.000 | 0.04 | 2.625 (2-5/8) | 12 | 12 | 48 |

*Workable I.D. length of the cuff. All lengths will be supplied with ‘B’ dimension cuffs (straight ends).

All pressures are calculated and not based on actual testing.

ID is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.