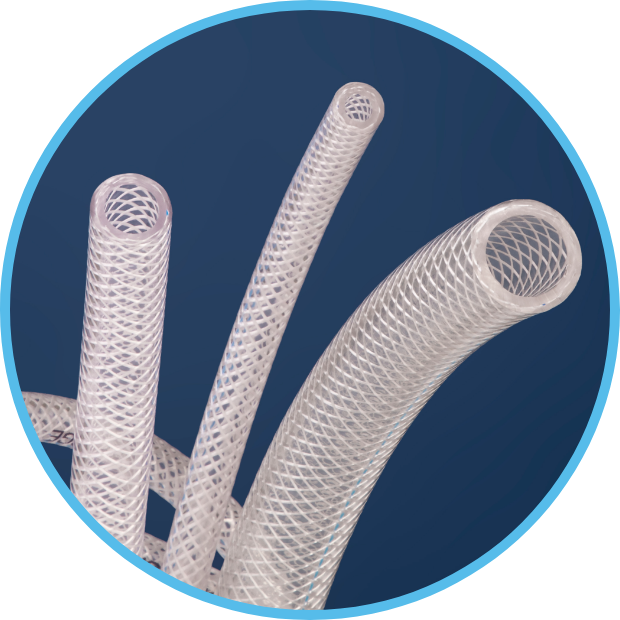

Nylobrade® NSF Listed

Braid Reinforced PVC Hose

Features

- Open mesh polyester braiding permanently encapsulated in walls of clear, flexible PVC tubing

- Phthalate, DEHP and BPA free

- Raw materials meet California Proposition 65

- Listed by the National Sanitation Foundation for food equipment materials (NSF-51)

- Non-toxic raw materials conform to USP Class VI and FDA standards

- Offers much greater pressure capabilities than unreinforced PVC tubing

- Mirror smooth interior permits outstanding flow characteristics

- Crystal clear for full visual flow^

- Corrosion and abrasion resistant with flexibility similar to rubber but with much longer life

- REACH and RoHS compliant

- Well suited for food and beverage applications including non-fatty aqueous, milk and alcoholic beverages (less than or equal to 8% ABV)

Applications

Beverage Lines • Chemical Transfer • Coolant Lines • Filling Lines • Food Handling • Hydraulics • Instrumentation Lines • Material Handling • Medical • Oil & Fuel • Pneumatics • Potable Water • Spray Systems • Water & Fluid Feeds

Recommended

Fittings & Clamps

Physical Properties**

Hardness, Shore A ±5

Tensile Strength, psi

Elongation at Break, %

Brittle Temperature, °F

Max. Operating Temperature, °F

Max. Operating Temp. for NSF, °F

80

2500

300

-50

175

140

Notes

Clear NYLOBRADE is made from non-toxic raw materials that conform to Food and Drug Administration (FDA) standards for use in food contact applications. Its NSF listing makes NYLOBRADE an excellent choice for drinking water applications, those involving water at temperatures up to 60°C (140°F), and food processing applications.

NYLOBRADE is generally unaffected by most oxidizing and reducing agents. Diluted acids and alkalies have little effect, though if highly concentrated tend to make the hose less pliable. If chemical resistance is in question, in-plant tests are suggested.

Gasoline and oils will harden PVC over periods of intermittent use. In these applications, continuous use will slow the hardening process.

Click here to review the PVC Products – Material & Regulatory Summary

^NYLOBRADE HP (High Pressure) sizes 3/8” I.D. and up have a tighter braid pattern and, therefore, reduce the visual flow contact and increase the hose’s resistance to bending & flexing. Heavier walls on similar I.D.s will be more resistant to kinking.

Any information presented on this webpage or in related promotional materials is being presented solely for informational purposes and does not create any representation from NewAge to any buyer regarding a product’s fitness for a particular use or that a particular use of the product by a buyer (including incorporation into a medical device) would comply with all applicable laws and regulations. NewAge’s standard terms and conditions (found here) will be the sole and exclusive legal agreement between the parties with regards to any purchased products.

Specifications

| Part Number | Note | ID (in.) | OD (in.) | Wall (in.) | Wall Type | Available Lengths (ft.) | Working PSI (at 70°F) | Calculated lbs./100 ft. |

|---|---|---|---|---|---|---|---|---|

| 1000076 | .125 (1/8) | .315 | .095 | Standard | 100 | 465 | 3 | |

| 1000230 | [B] | .188 (3/16) | .394 | .103 | Standard | 100, 300, 500 | 315 | 5.06 |

| 1030309 | .250 (1/4) | .435 | .093 | Thin | 100 | 316 | 5.35 | |

| 1000307 | .250 (1/4) | .453 | .102 | Standard | 100 | 300 | 6.03 | |

| 1020061 | .250 (1/4) | .500 (1/2) | .125 (1/8) | High Pressure | 100 | 400 | 7.9 | |

| 1000461 | .313 (5/16) | .531 (17/32) | .094 | Standard | 100 | 280 | 7.77 | |

| 1030540 | .375 (3/8) | .575 | .100 | Thin | 100 | 215 | 8.02 | |

| 1000538 | .375 (3/8) | .600 | .113 | Standard | 100, 500 | 230 | 9.26 | |

| 1020075 | .375 (3/8) | .625 (5/8) | .125 (1/8) | High Pressure | 50, 100, 300 | 265 | 10.5 | |

| 1030694 | .500 (1/2) | .710 | .105 | Thin | 100 | 191 | 10.73 | |

| 1000692 | .500 (1/2) | .728 | .114 | Standard | 100, 300, 500 | 215 | 11.82 | |

| 1020096 | .500 (1/2) | .850 | .175 | High Pressure | 100 | 258 | 20 | |

| 1000846 | .625 (5/8) | .906 (29/32) | .141 | Standard | 100, 300 | 200 | 18.17 | |

| 1000923 | .750 (3/4) | 1.024 | .137 | Standard | 100, 300, 500 | 150 | 20.53 | |

| 1020117 | .750 (3/4) | 1.125 (1-1/8) | .188 (3/16) | High Pressure | 100 | 233 | 30 | |

| 1001154 | 1.000 | 1.299 | .150 | Standard | 100 | 130 | 29.03 | |

| 1020005 | 1.000 | 1.375 (1-3/8) | .188 (3/16) | High Pressure | 100 | 185 | 37.8 | |

| 1001308 | 1.250 (1-1/4) | 1.732 | .241 | Standard | 100 | 110 | 60.7 | |

| 1020012 | 1.250 (1-1/4) | 1.732 | .241 | High Pressure | 100 | 150 | 60.7 | |

| 1001385 | 1.500 (1-1/2) | 1.929 | .215 | Standard | 100 | 70 | 62.12 | |

| 1020019 | 1.500 (1-1/2) | 1.950 | .225 | High Pressure | 100 | 90 | 65.5 | |

| 1001462 | 2.000 | 2.500 (2-1/2) | .250 (1/4) | Standard | 100 | 50 | 95.02 | |

| 1020026 | 2.000 | 2.500 (2-1/2) | .250 (1/4) | High Pressure | 100 | 133 | 95.02 |

[B] Limited stock item; lead times and minimums may apply — call for details.

Add length suffix to part number when ordering. Example: 100 ft. of 1/8″ I.D. x .315″ O.D. is part number 100 0076-100.

Working pressures are calculated from burst testing using a 3:1 safety factor. Application testing is recommended.

ID is the critical dimension for fittings application.

Custom Capabilities

Cut Pieces

Size

Color

Hot Bond

Heat Form

Hardness

In-Line Cutting

Custom Layline

All custom products are subject to minimum order quantities and lead times. For other custom options, please contact us.